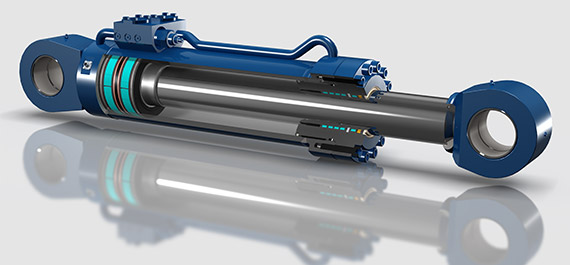

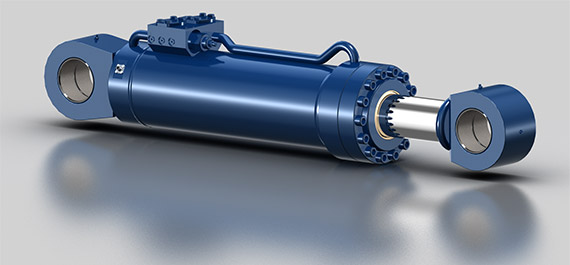

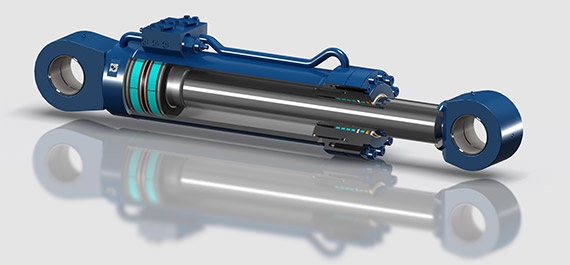

Texas Hydraulics’ construction grade cylinders are designed for extreme duty applications. They have a high cycle fatigue resistance, forged end mounts, chrome plating, and induction hardened rod. A bolted head design allows for easier serviceability, and the buffer seals help to extend rod seal life. This cylinder is ideal for applications in construction, earth moving, forestry, demolition, and mining.

Applications: Construction & Infrastructure

Features

- Cylinder Designed for Extreme Duty Applications

- Bolted Head Design for Serviceability

- High Cycle Fatigue Resistance

- Friction Welded Rod Mounts Available

- Forged End Mounts

- Chrome Plated and Induction Hardened Rod

- Base and Rod End Cushions with Fast Start

- Buffer Seals to Extend Rod Seal Life

- Precision Wear Rings on Piston and Rod

- 4 Piece High Pressure Piston Sealing System

- O-Ring Boss or 4-Bolt Flange Porting

- 5000 psi (345 bar) Continuous

- 6000 psi (415 bar) Intermittent

- 120 ft/min Rod Speed (37 m/min)

- -35 to 220 Degrees Fahrenheit (-37 to 104 Degrees Celsius) Continuous

Optional Features

- Valve Integration

- Position Sensing

- Custom Mounting

- Chrome Over Nickel Rod Plating for Additional Corrosion Resistance